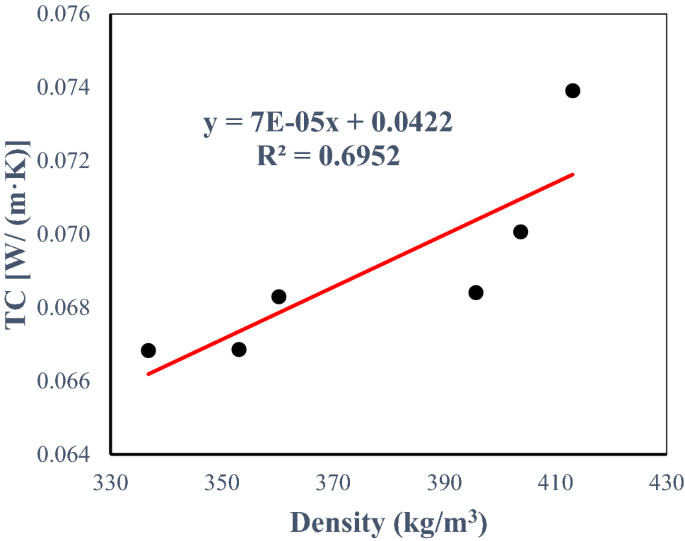

Thermal Barrier Coating Density

Processes for thermal spray coating the following are processes through which thermal barrier coatings can be applied to your company s products components surfaces and parts.

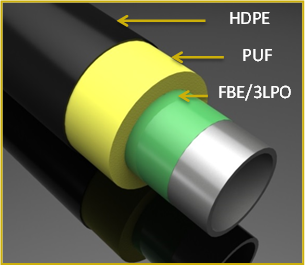

Thermal barrier coating density. Based on the experiences from the aerospace industry thermal barrier coatings tbcs have been explored and have shown great promise to improve the efficiency of internal combustion engines. Spray and fuse hard facing to apply a vast array of materials onto a substrate the utilization of a combustion powder spray gun is required for this process. Thermal barrier coatings for diesel engines have been studied in the last 30 years and numerous methods and layer materials have been investigated. Applying upon said bond coat layer a thermal barrier coating composition comprising a particle size distribution of no less than about 8 microns and no more than about 88 microns.

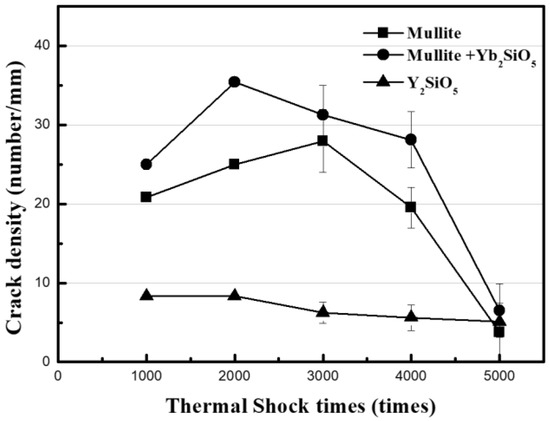

A serious problem concerning the thick tbcs is relatively low thermal shock resistance when the coating. Also thermal barrier coatings on other elements of combustion chamber of internal combustion engine offer advantages including fuel efficiency multifuel capacity and high power density. A reduced thermal conductivity thermal barrier coating having improved impact and erosion resistance for an underlying metal substrate of articles that operate at or are exposed to high temperatures. This coating comprises a zirconia containing ceramic composition having a c a ratio in the range of from about 1 0057 to about 1 0123 and stabilized in the tetragonal phase by a stabilizing.

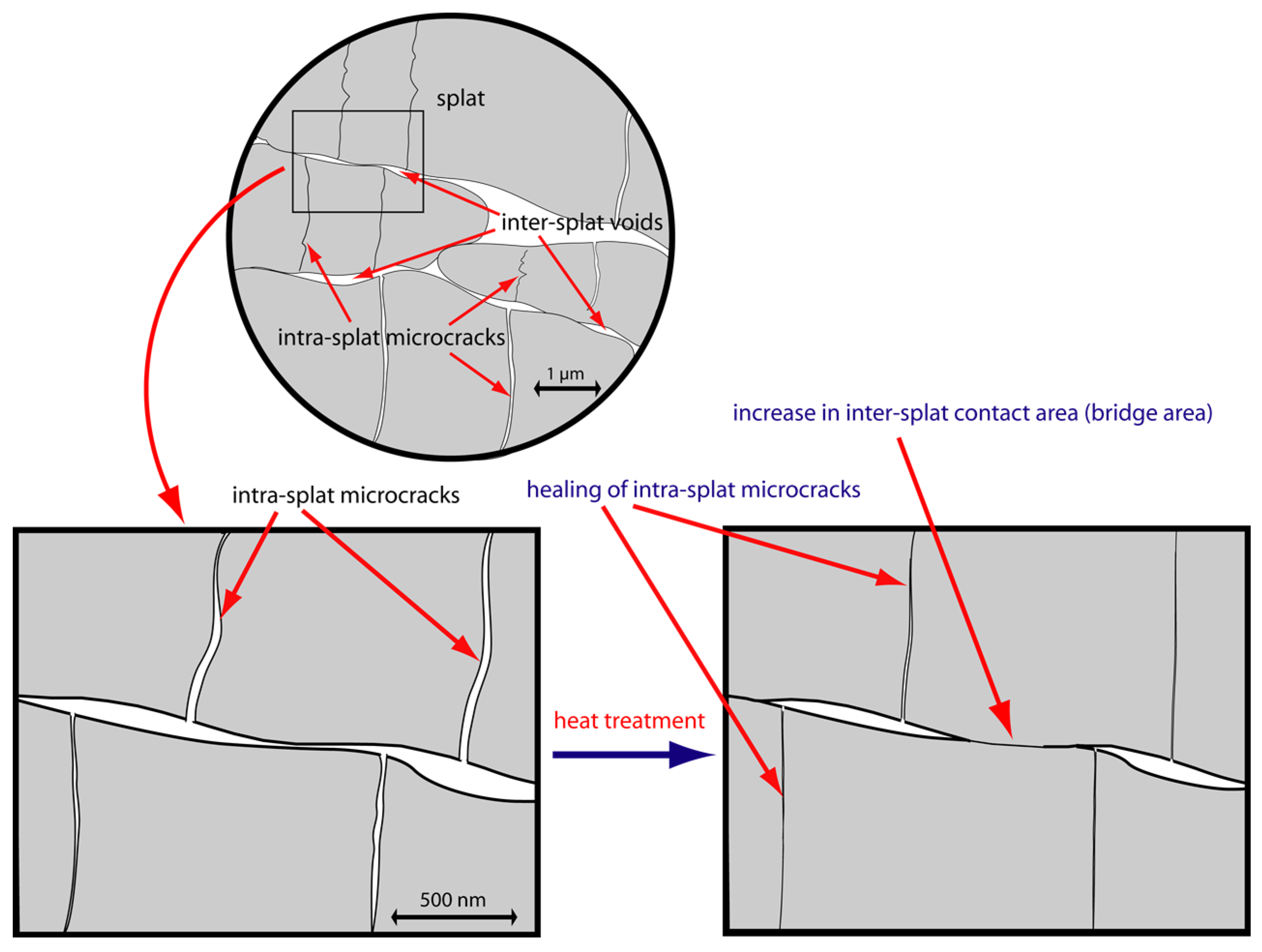

Update on 3 4 inch plywood as a thermal barrier i was recently looking at this topic in more detail for a project it appears that one of the amendments to the 2015 i code now explicitly allows 3 4 okay 23 32 wood structural panel as an interior thermal barrier. A process for coating an article includes the steps of applying a bond coat layer onto at least one surface of an article. Thermal barrier coatings with thickness greater than 1 mm achieve better heat insulation than thin thermal barrier coating with thickness of the order of a few tenths of a mm however present new problems not seen with thinner coatings. Fastblock 200 series a solvent based moisture cured fire barrier and thermal insulation coating for various application of aircraft firewall structure or other components.

Product shelf life 6 months 77 f dry place in sealed outer container. Heat treating said thermal barrier coating composition at a temperature of between about. Thermal barrier coatings tbcs are advanced materials systems usually applied to metallic surfaces operating at elevated temperatures such as gas turbine or aero engine parts as a form of exhaust heat management these 100 μm to 2 mm thick coatings of thermally insulating materials serve to insulate components from large and prolonged heat loads and can sustain an appreciable temperature.