Underground Mining Equipment Selection

Principal course topics include the following.

Underground mining equipment selection. Basic types of mining equipment and associated pws selection criteria. Once a decision has been made to go underground the specific mining method selected depends on the size shape and orientation of the ore body the grade of mineralization the strength of the rock materials and the depths involved. The equipment selection process for an underground mine design plan has an extremely wide scope as there are a myriad of parameters to consider when incorporating mobile and stationary equipment in hard or soft rock mining applications. Selection of the equipment package for underground coal mines while surface mining will continue to play dominant role to meet the production target there is a persistent effort to enhance the underground production from its present level by introducing innovative technologies.

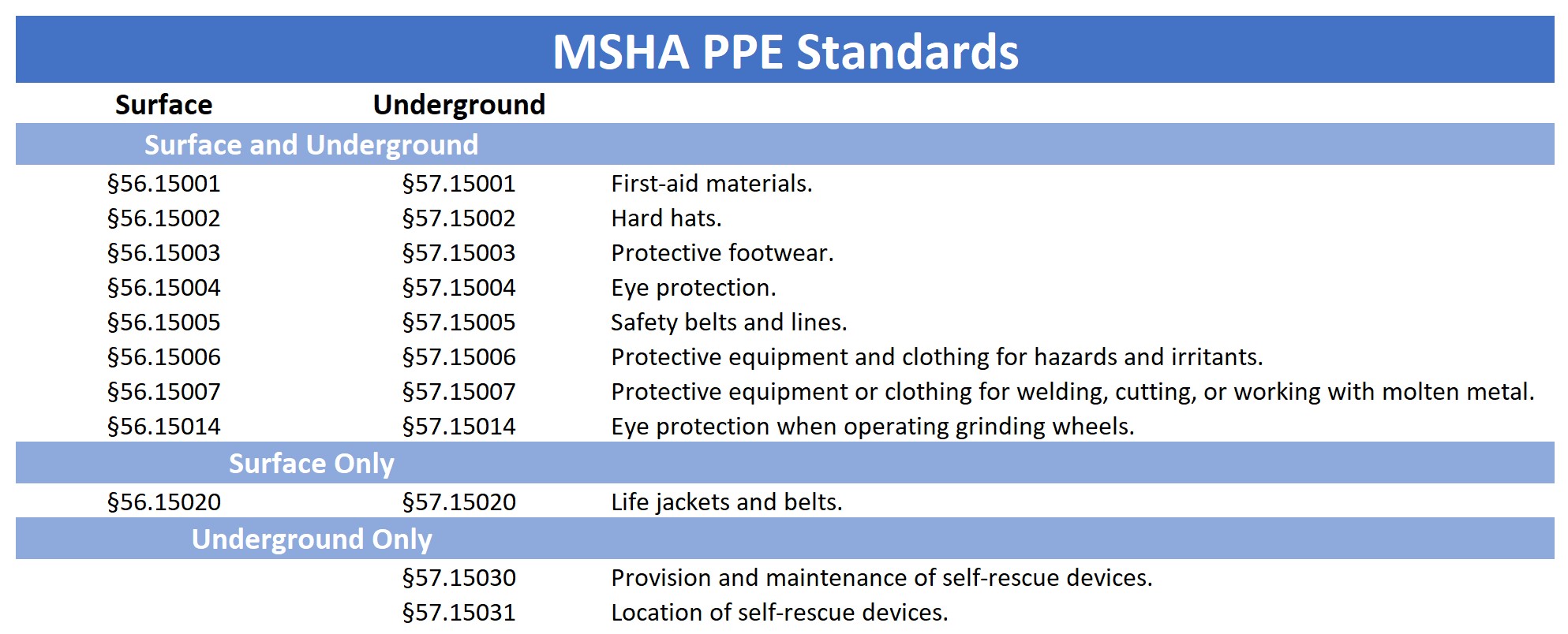

Equipment selection is based upon mining method and related production performance and cost requirements. Underground mining requires that any electrical system meet mine safety and health administration guidelines msha 2000 for safe operation in potentially hazardous areas where ignition of methane air or coal dust is a safety concern. Though different techniques are used to extract base metals precious metals nonmetallic minerals diamonds and coal the hazards do not differ that much. The deeper the mine however the greater the risk.

Underground mining operations around the world pose similar risks to worker safety and health. Mining method selection is based upon physical geological economical and environmental conditions and constraints. For example if the ore is very high grade or carries a high price then a higher cost method can be used.