Vac Mat Vacuum Clamping System

Vac u clamp is not only the leader in vacuum forming technology but also vacuum laminating technology.

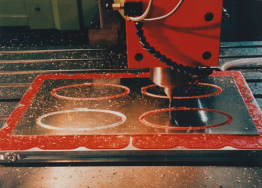

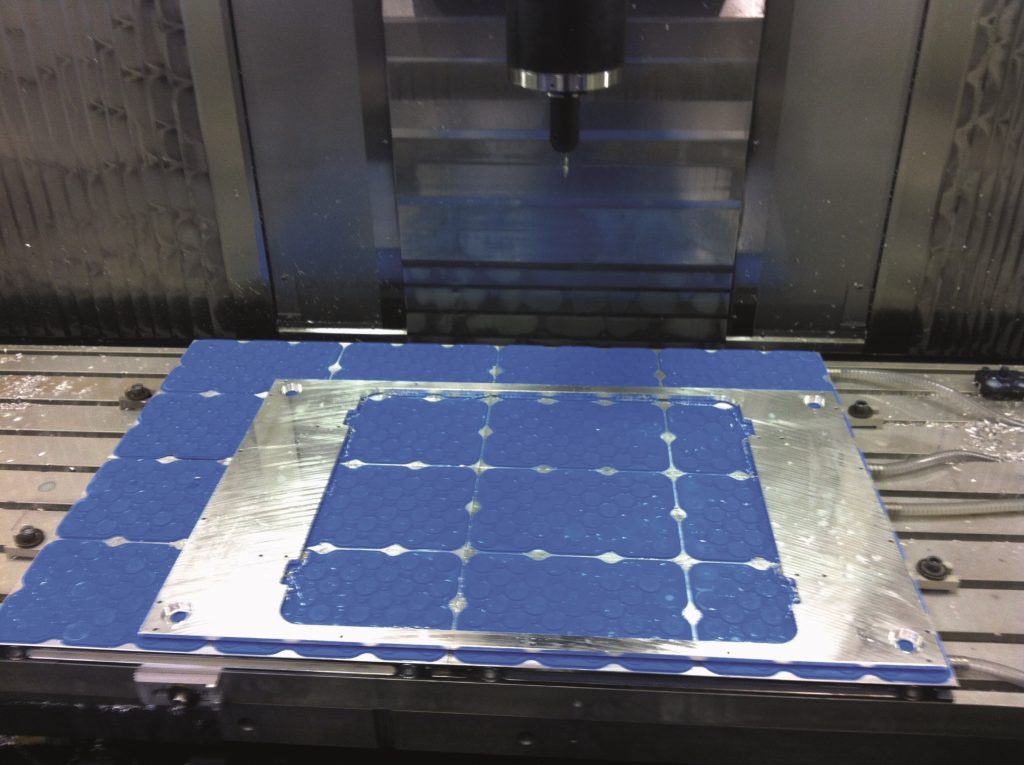

Vac mat vacuum clamping system. The vacuum clamping of certain part shapes and configurations cannot be successfully held by a standard design. Vac mat polymer mats for milling cutouts and contours. With vac mat polymer mats from witte workpieces can be machined completely in one vacuum clamping process. The parts may be very small or intricate and require a special solution.

Our full line of vacuum presses range from the s p series vacuum presses which is our smallest vacuum press. Vacuum chucks fixtures and clamping systems can be awesome productivity enhancers in any shop but they re especially helpful for rapid prototyping and sheet work e g. The vacuum pressing bag system which completely envelops the woodwork and the vacuum press table frame system with a hinged lid that drops down over the wood panel being pressed. It is not necessary to cover all suction cups only enough to provide adequate clamping force to properly secure the part during machining.

Signs and electical panels. Venturi valves are obtainable on turning machines vacuum is catered for via rotating joints di rectly through the hollow spindle of the machine vacuum clamping systems with integrated pumps tanks energy mo dules can be operated completely independently and free from any external supply lines complex vacuum fixtures can be equipped with mechanical pneumatic hydraulic or electrical clamping positioning and or handling units. Po box 1043 4652 west rosecrans ave. Vac mat allows milling of cutouts slots etc.

Hawthorne ca 90250 6896 phone. In turning applications vacuum chucks are popular for turning wooden bowls and spheres because they can hold the work without marring the surface. With vacuum applied to the underside of the vac mat pad each suction cup will provide holding force on the work piece material. Next is our mid sized cold vacuum press which includes our f series flip top vacuum presses.