Vacuum Dewatered Flooring Is Code

Laying guide rails to every 4 meters using ms channels or as required in straight lines along the line dori taking.

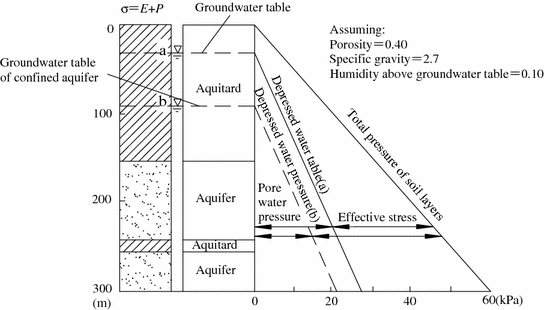

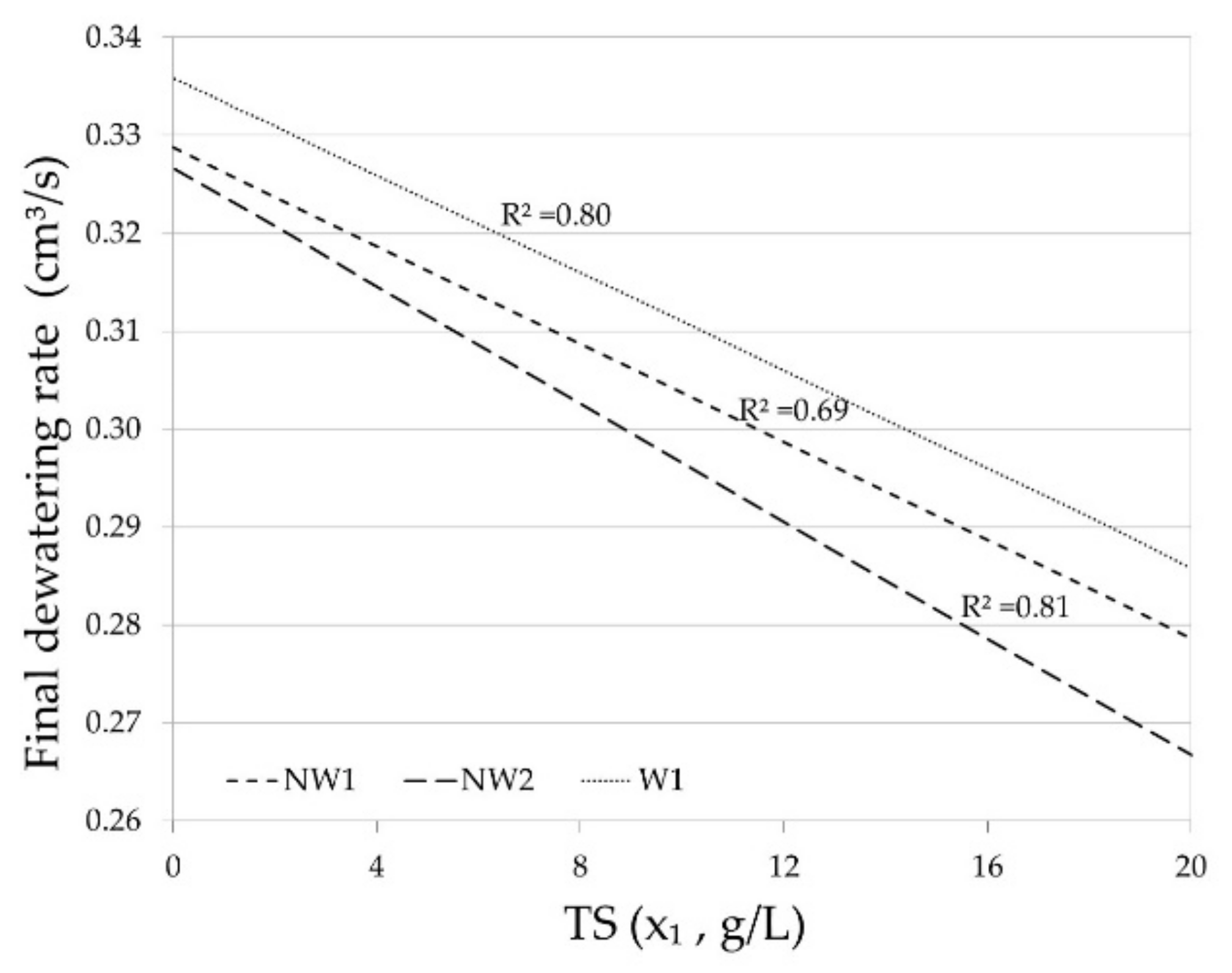

Vacuum dewatered flooring is code. E 2013 vacuum dewatered flooring in durable construction international journal of civil engineering research vol. In this technique the excess water after placement and compaction of concrete is sucked out with the help of vacuum pumps. This technique is effectively used in industrial floors parking lots and deck slabs of bridges etc. The vacuum dewatered vd flooring method is a system for laying high quality concrete floors with superior cost effectiveness.

Vacuum dewatered flooring vdf vacuumdewateredflooring civilengineering. A vacuum dewatered concrete flooring method can be defined as vacuum dewatered flooring v d f is a special type of flooring technique to achieve high strength longer life better finish and faster work. The magnitude of applied vacuum is usually about 0 08 mpa and the water content is reduced by upto 20 25. Surplus water from the concrete is removed immediately after placing and vibration reducing the watercement ratio to an optimum level.

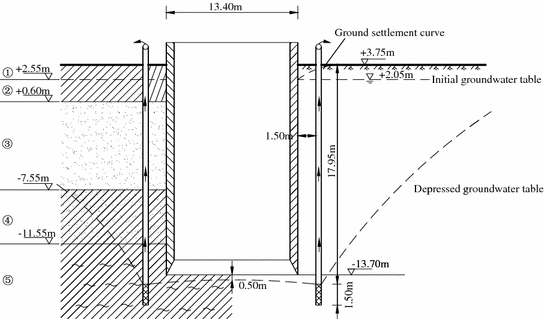

Vdf flooring specifications or flooring specifications or vdf flooring methodology or vdf flooring procedure or vacuum dewatered flooring technical specification or vacuum dewatered flooring procedure tying line dori threads as per the slope requirements br bull. The key to the use of this method is the dewatering of concrete by vacuum process. The vacuum dewatering process consists of leveling compacting and vacuum dewatering the concrete flooring by using vibrating screed vacuum pumps suction mats filter pads accessories etc. This standard which was first published in 1963 is now being revised taking into account the experience gained in the.

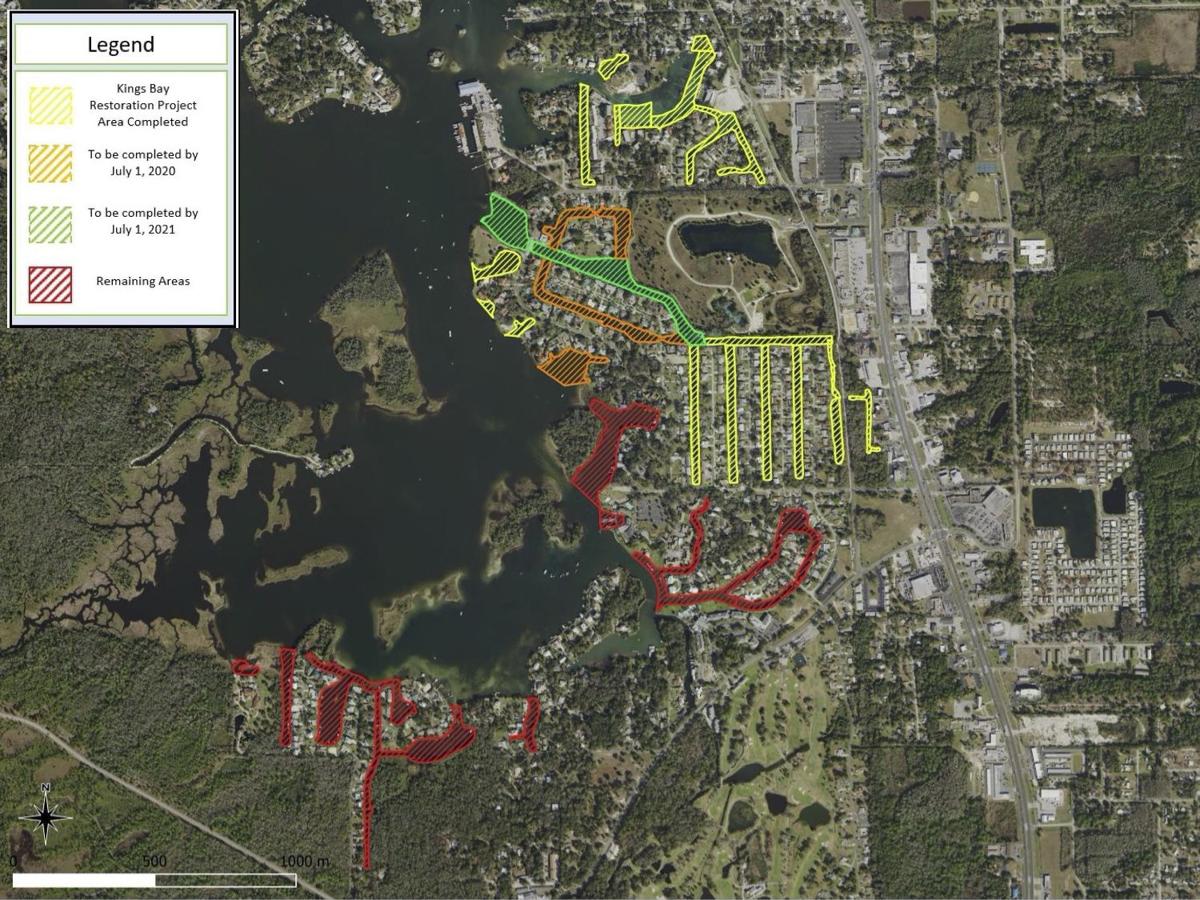

Benefits of vacuum dewatered. Theory and practice 14 4 vacuum. This type of floor is suitable for high abrasion and heavy traffic movement seminar 2017 18 4 6. Vacuum dewatered flooring abstract.